"The first casting must be good"

These words, spoken by CWC founder George Cannon in 1908, still inspire CWC's attention to quality and customer focus.

Since then, CWC has served as a leader in the production of camshafts for global automotive companies. With such a legacy of quality and service, it’s no wonder we believe “The First Casting Must Be Good.”

A Leader in Castings

CWC manufactures castings (crankshafts, camshafts, balance shafts, and more) for a variety of applications including automotive, agricultural and power sports programs. In addition to producing rough castings, CWC has the capability to undertake rough machining and material hardening. CWC is a technical leader in lobe hardening required in most modern engine applications and is sought after for its technical expertise and focus on quality. Using flame heat, oil quenching and cryogenic freezing and tempering techniques, in addition to an austempering process, CWC alters the metal microstructure to each customer’s unique specifications.

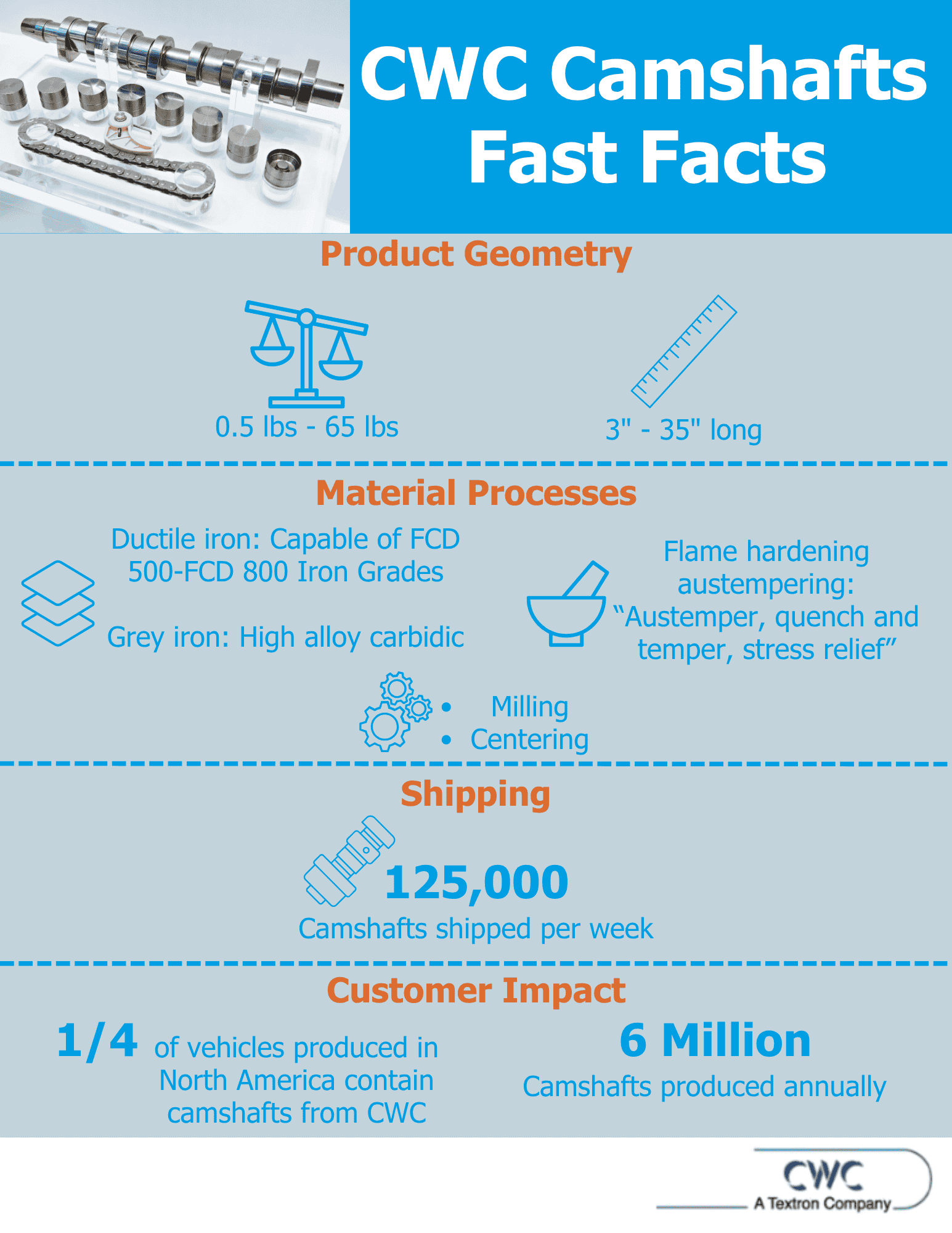

Camshafts "Fast Facts"

CWC Camshafts in Vehicles Nationwide: Our 287,000 sq. ft. facility located in Muskegon, Michigan, produces more than 6 million camshafts annually. In fact, roughly 25 percent of the vehicles manufactured in North America have castings produced at CWC.

Materials & Processes

Materials

- Ductile Iron: FCD 500-FCD 800

- Alloyed Gray Iron: High Chrome carbidic material

Casting / Molding

- Cupola Melt – 1 Cupola

- Holding Furnaces – (2) 50 ton Ajax

- Horizontal Cope & Drag / Green Sand Molding

Rough Machining

- End Milling

- Centering

Flame Hardening

- CWC has been flame hardening camshafts for many years. We make approximately 5 million flame-hardened camshafts annually and have never had a failure in the field.

- As the single-source camshaft supplier to Toyota North America, we understand the importance of quality in our flame-hardening process.

Austempering/Selectively Tempered Ductile Iron (SADI)

- CWC's selective tempered ductile iron (SADI) process exhibits the strength, ductility and wear-resistance for applications up to 255 KSI HERTZ. This CWC innovation allows us to offer our customers camshafts that can withstand higher engine stress and significant cost savings when compared to steel or assembled camshafts.

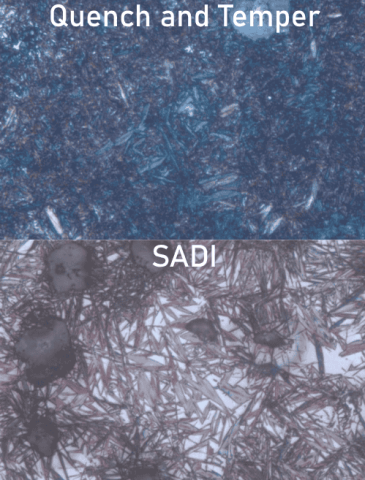

Development Roadmap - SADI Process

CWC's SADI creates a structure with superior wear resistance compared to traditional quench and temper hardening

- Material work hardens under loading

- Hardened case of material creates internal stress to counteract loading

CWC: A Long-Standing Tradition

It started in 1905 with a verbal agreement between Donald Campbell, Ira Wyant and George Cannon to put $10 a month into a savings fund to provide working capital for business opportunities. Three years later, on April 20, the Campbell, Wyant and Cannon (CWC) Foundry Company was founded.

By 1947, CWC was one of the largest foundry companies in the United States, owning or managing over a dozen foundries in the Midwestern U.S. On April 19, 1956, CWC was acquired by Textron Inc. In 2003, CWC became part of the Kautex family, after Textron sold the remaining assets of its automotive group.

Today, roughly one-fourth of the vehicles produced in North America contain CWC camshafts. The foundry, located in Muskegon, MI, makes 6 million camshafts a year, and ships 25,000 cams per day.

The facility produces camshafts for Toyota (all North America production), General Motors, Stellantis and Ford Motor Company, as well as aftermarket customers. Although most customers are U.S. and Canada based, CWC also supplies camshafts to customer facilities in Mexico and has the capability to ship to Asia and overseas countries.

Environmental Impact at CWC

- 100% recycled bulk materials

- Won Kautex awards for work on Scope 2 emissions

- Finalist for Textron Sustainability Awards for Circular Manufacturing

- Minimal waste generated for landfills

- Better than industry average for recycling of foundry waste

- 65% of waste is recycled (Almost 10,000 tons of recycled material per year)

- Injury rates - much lower than industry average

- CWC TRIR = 1.45

- Foundry average = 7.3-8.2

- Michigan Clean Corporate Citizen