Road Tested and Production Ready: Pentatonic Battery Enclosures

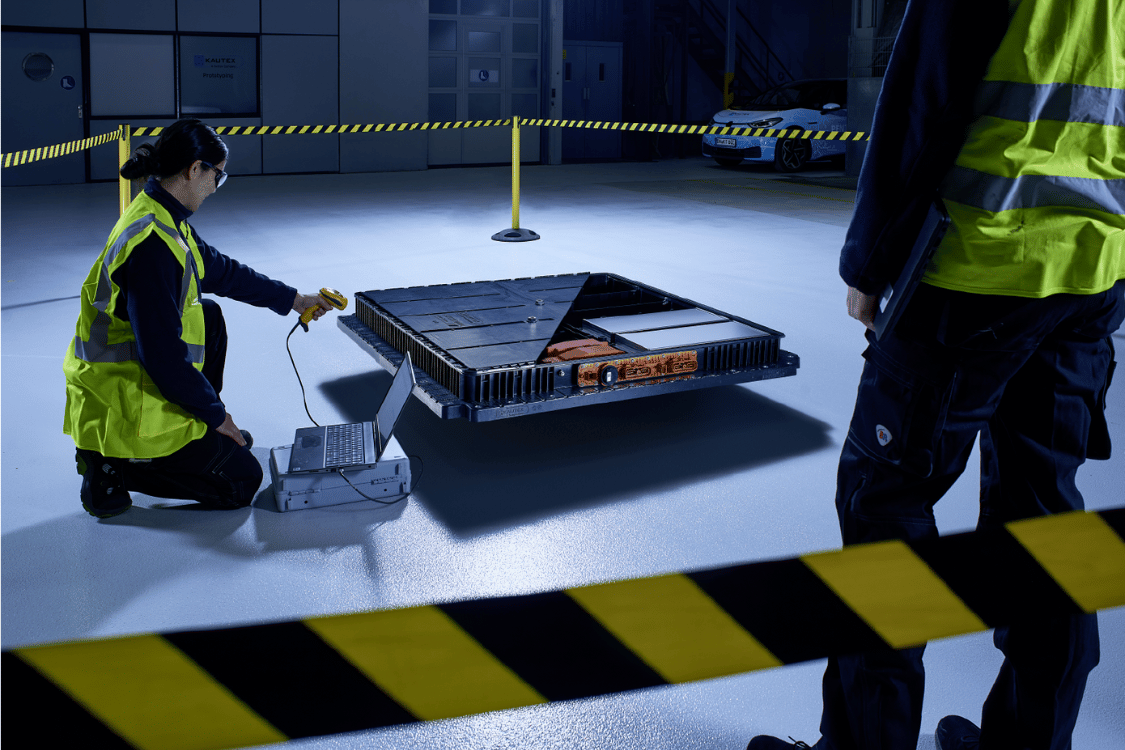

Road Tested

In 2021, we purchased and retrofitted a hybrid vehicle with our composite Pentatonic Battery Enclosure and soon put over 30,000 miles on it, driving it from coast to coast in the US.

In 2022, we purchased and retrofitted a full battery electric vehicle in Germany and put our Pentatonic Battery Enclosure to the test on race tracks, in New Mobility rallies, and driving it over 8400 km around the country.

In 2023, we added to our of electric vehicles and retrofitted our product into another full battery electric vehicle, this time in the US. Follow our Instagram for updates along the way!

One product; three demonstrators. Our Pentatonic Battery Enclosures, installed on three vehicles, have tracked more than 35,000 miles. Our latest demonstrator boasts a system produced by our Pinghu team in China, where we have installed a compression molder to run customer samplings and to complete our own internal testing. We stand ready to serve you.

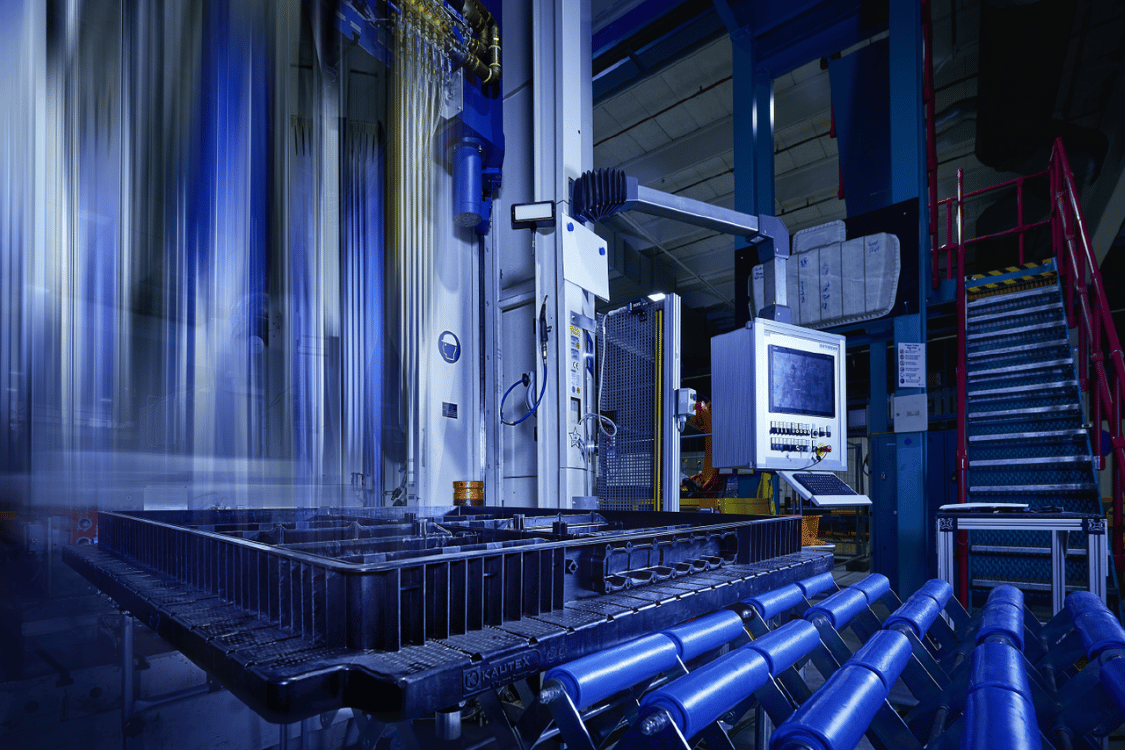

Production Ready

Kautex's latest demonstrator vehicle showcases a Pentatonic battery housing built by Kautex at its Pinghu facility. Commissioned in 2022, the compression molding line in Pinghu, China has already supported customer trials and samplings - and produced Kautex's own Pentatonic battery enclosure for its demonstrator vehicle.

Benefits

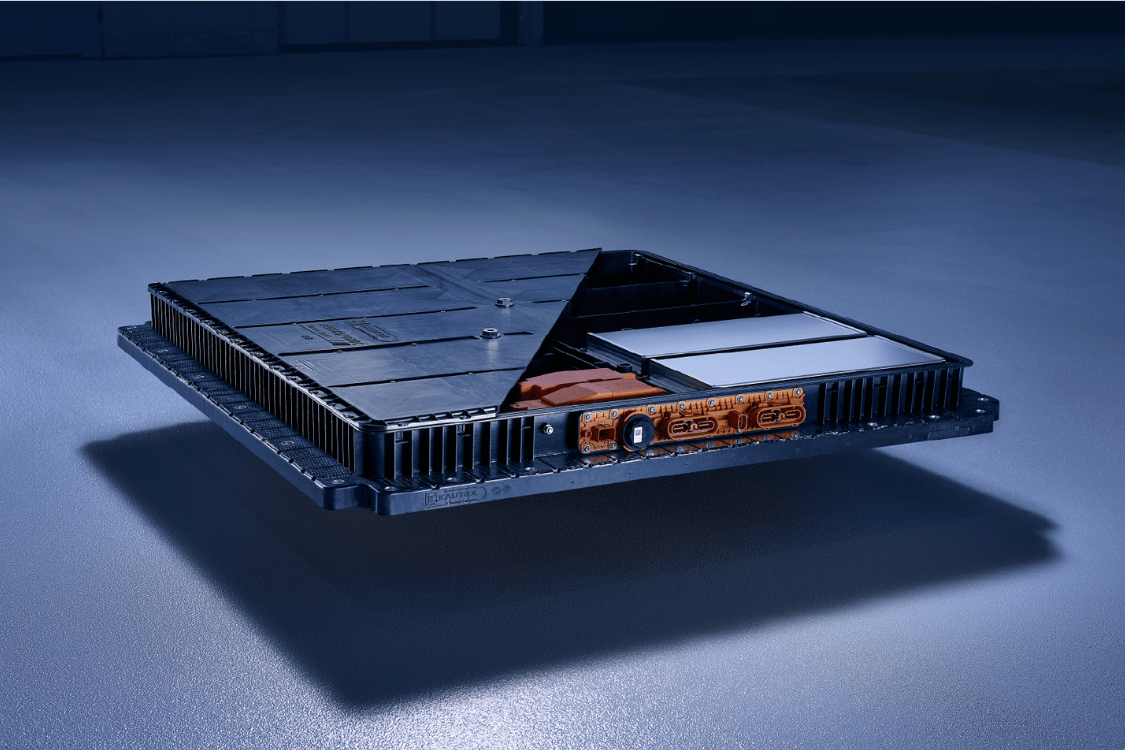

Safety

The materials and processes we use make safety the highest priority when it comes to production and application. Our non-conductive housing material reduces risk of electrical shock and corrosion, unlike our steel and aluminum counterparts.

Feature Integration

Features and thermal management components like cooling plates are integrated into one fully capable, lightweight system. Reduction of secondary process steps simplifies the assembly process, reducing the customer bill of material and improving cost by up to 20 percent. Fewer assembly steps reduce the number of sealing joints, which lessens the risk of leakage.

Manufacturing Process

Our "one shot" process uses reinforced materials and integrates structural elements directly into the injection or compression molding process, eliminating timely assembly steps at the customer's facility.

Benefits include fewer secondary operations, such as welding and riveting, shorter cycle times than steel and aluminum counterparts, and improved leak-tightness.

Weight

Pentatonic weighs up to 30% less than its steel and aluminum counterparts, which improves the range of the vehicle and allows the opportunity to adjust chassis components – such as suspension and brake systems.

Pentatonic allows the opportunity for maximum payload capacity while limiting CO2 emissions as well as energy consumption in both the vehicle and within the supply chain.

Volumetric Advantages

The Pentatonic Battery Enclosures require less clearance between the housing and the modules due to the isolating characteristics of our materials and the increased integration (e.g cooling plates) during the production process.

Homologation

As the pioneers in plastic fuel tank production, our decades of expertise with fire tests, leak tightness proofing, and crash tests are utilized and extended to the requirements in designing as well as producing composite battery systems, such as ECE R100 or GB38031-2020.